이 BMS 테스터는 최대 300A 충전 및 400A 방전 전류를 지원하는 1~24 시리즈 리튬 배터리 팩을 지원합니다. 과충전, 과방전, 과전류, 단락, 밸런싱 등 주요 보호 파라미터를 빠르고 정확하게 테스트할 수 있습니다. 원통형 및 파우치형 배터리 모듈의 고전력 BMS 검증에 이상적입니다.

상표 :

ACEY제품 번호. :

ACEY-BP24-300A400A맞춤화 :

OEM&ODM Available주문(MOQ) :

1 Set규정 준수 :

CE Certified지불 :

T/T, L/C, PayPal, West Union, Alibaba Trade Assurance, Etc보증 :

One Year Warranty With Lifetime Support제품 원산지 :

China패키지 :

Internal: Anti-Collision Protectio, External: Plywood Case선적 :

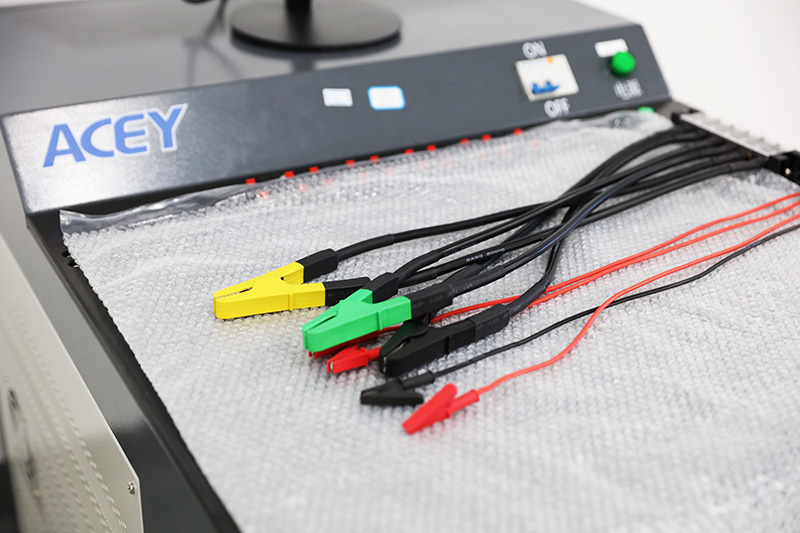

By Air, Sea, Express, etc.1-24 BMS 테스터 300A 충전 400A 방전

기능 소개

1) 1-24 시리즈 배터리 관리 시스템 테스터, 높은 수준의 자동화, 빠른 테스트ing 속도 및 높은 테스트ing 정확도. 테스트 함수 에누리 보호, 과충전 회복, 과방전 보호, 과방전 회복, 과전류 보호 (과충전 전류 및 과방전 전류), 내부 저항, 자가 소모, 단락 보호, 과충전 보호 시간, 과전류 보호 시간, 과방전 보호 시간, 평형 전류, 평형 전압 등.

2) MCN 배터리, LiFeO4 배터리, 코발트산 배터리의 BMS를 테스트할 수 있습니다.

3) 이 기계는 컴퓨터에 연결해야 하며, 이 시스템에는 일반적으로 XP 시스템이 필요하고, 테스터와 컴퓨터의 인터페이스는 RS232입니다.

장치의 장점

1. 사이클: 사이클 시간: 1~9999회

2. 실험실 모드에서는 섹션의 전압 값을 임의로 조정할 수 있습니다.

3. 지속적으로 충전 및 방전 전류를 제공할 수 있습니다.

4. 프로그래밍을 사용하여 장치는 보호 보드의 각 표시기의 사이클 수를 중단 없이 수행합니다.

5. 로그 추적, 로그 기능을 통해 전체 테스트 프로세스의 작업 기록, 이상 기록을 포함하여 테스트 프로세스의 추적성을 확보할 수 있습니다.

6. 데이터 처리, 인간-기계 인터페이스

7. 테스트 데이터는 EXCEL 파일에 저장됩니다.

8. RS232 인터페이스는 장치와 호스트 컴퓨터 간의 인터페이스로 사용되어 안정성과 실시간 데이터 수집을 보장할 수 있습니다.

9. 정확도 교정/소프트웨어 교정

10. 스위핑 코드 시작 기능 포함

11. MES 시스템 인터페이스

12. 능동적 이퀄라이제이션(사용자 정의 가능)

13. 균등화 전류(사용자 정의 가능)

14. 통신 프로토콜 테스트(선택)

테스터 기능

아니요. | 기능 | 범위 | 정확성 | 단위 |

1 | S엘프 소비 단일 세포의 | 0--500 | ±0.1 | uA |

2 | S엘프 소비 | 0--5000 | ±1 | uA |

3 | 과충전 전압 | 500--5000 | ±1 | mV |

4 | O과징금 회수 전압 | 500--5000 | ±1 | mV |

5 | 과충전 전압 보호 지연 | 0--10000 | ±1 | mS |

6 | O버전디스요금 전압 | 500--5000 | ±1 | mV |

7 | O버전디스전하 회복 전압 | 500--5000 | ±1 | mV |

8 | 위에디스충전 전압 보호 지연 | 0--10000 | ±1 | mS |

9 | 과충전 보호 전류 보호 값 | 0.1--300 | ±0.01 | A |

10 | 과충전 보호 전류 보호 지연 | 0--20000 | ±1 | mS |

11 | 위에디스충전 보호 전류 보호 값 | 0.1--400 | ±0.01 | A |

12 | 위에디스충전 보호 전류 보호 지연 | 0.1--20000 | ±1 | mS |

13 | 평형화 기능 개방 전압 | 500--5000 | ±1 | mV |

14 | 이퀄리징 전류 | 1--500 | ±1 | mA |

15 | 충전 전류 | 0.1--300 | ±0.01 | A |

16 | 방전 전류 | 0.1--300 | ±0.01 | A |

17 | 충전 시간 | 0--100 | ±1 | S |

18 | 방전 시간 | 0--100 | ±1 | S |

19 | 단일 세포의 차이엘프-컨소비e | 0-500 | ±0.1 | uA |

20 | 저항 | 0-999 | ±1 | mΏ |

21 | 단락 보호 시간 | 0--5000 | ±1 | uS |

22 | 단일 셀의 충전 전압 | 500--5000 | ±1 | mV |

23 | 단일 셀의 방전 전압 | 500--5000 | ±1 | mV |

24 | 개방 회로 전압 | 120000 | ±1 | mV |

25 | 전압 아날로그의 수 | 24 | 0 | PC(피씨) |

메인 루프 테스트의 매개변수:

프로젝트 | 매개변수 |

전압 | 120000mV |

전압 분해능 | 1mV |

Vol티지 정확성 | ±0.1% |

방전 전류 | 0.1A ~400A |

현재의 해결 | 1mA |

현재 정확도 | ±(0.1%) |

다른 | 충전 및 방전 회로가 완전히 분리되어 있습니다. |

모든 시리즈의 매개변수es 셀:

프로젝트 | 매개변수 |

각 셀의 출력 전압 | 500mV ~ 5000mV |

In각 셀의 전압을 넣다 | 500mV ~ 5000mV |

전압 분해능 | 1mV |

Vol티지 정확성 | ±0.05% |

균등화 전류 | 500mA |

전원 상자의 매개변수(과전류)t):

프로젝트 | 매개변수 |

제어 가능한 아날로그 전류 범위 | 0.1A -400A |

제어 가능한 아날로그 전류 정확도

| ±0.1% |

최대 출력 전압

| 5000mV |

기타 매개변수:

프로젝트 | 매개변수 |

소비전류 측정범위 | 1 ~ 5000uA |

소비 전류 측정 해결 | 0.1uA |

저항 | ACIR: 0-999mr |

보호 시간 | 과전류 보호 시간:0-999ms; 단락 보호 시간:0-999us |

1채널 신호 전압 출력: | 500~5000mV |

광고/다 | AD:16비트 DA:16비트 |

방전 모델 | CC |

24개의 아날로그 셀 | 입출력:500~5000mV, 전압 누적ra시:±0.1% |

C통신 속도 | 2채널 SBS 의사소통 비율:10~100Kbps |

기타 | 전압 샘플:0~5000mV 적산racy:±0.1% |

보호 기능 | 전체 보호(역접속 보호, 전압 저하 보호, 전압 상한 보호, 전류 상한 보호 포함), CC 충전 보호(비정상 전압 추세 보호, 비정상 충전 전류 변동 보호, 비정상 전압 변동 보호), CC 방전 보호(전압 추세 비정상 보호, 방전 전류 변동 비정상 보호, 전압 변동 비정상 보호 포함) |

C의사소통 | 인터페이스 RS232/DB9 C통신 속도 인터페이스:38400 장비의 모든 통신 포트는 격리되어 있으며, 낙뢰 보호 설계가 적용되었습니다. |

회로 구조 | 모듈식 구조로, 예비 부품 및 예비 부품을 이용하여 적절한 시기에 교체 및 수리가 가능합니다. |

기계 a건축 | 분할 캐비닛 |

안전 수준 | EN60950, GB4943 |

소음 | 에 따라 IEC62040-3, ≤70데시벨 |

보호 정도 | IP20 |

색상 | 실제 상황에 따라 |

번개 보호 | GB17626 레벨:II |

냉각 | 강제 공기 냉각, 출구 간 최소 20cm 간격 그리고 기입 |

시작 펄스 전압 | 장비 테스트, 실행 프로세스 시작 시 허용 가능한 최대 펄스 전압 ≤ (테스트 스트링 수 설정 * 단일 전압 설정) * 110%, T≤500uS; |

시작 펄스 현재의 | 장비 시험의 경우 과전류 시험 공정 시작 시 허용 가능한 최대 펄스 전류는 설정된 과전류 보호 값*120%의 상한값 이하, T≤1mS입니다. |

배선 방법 | 스프링 크림핑 |

Pr제품 디스플레이